Interview with James and Angela Brown of BLTC

Cigar Press – What led you to cigars?

Cigar Press – What led you to cigars?

James Brown – I was in the wine business in my early 20s and took a job in Tucson, Arizona called Anthony’s in the Catalina’s. I was a Sommelier at that restaurant. Anthony at that time also owned cigar stores called Anthony’s. They are still there but he doesn’t own them anymore. He was a big cigar enthusiast. Through working with him that really opened my eyes to what cigars really were. I smoked my first Padrón there. He did a lot of educating on the cigar side for me. That is really when my interest grew. It was kind of like wine for me at the time. I just threw myself all in. I was very much into wine, and then cigars were the same thing. I wanted to learn as much as I could and smoke as many different ones that I could get my hands on. From then on I have been an avid cigar guy.

CP – Did you go to school to become a Sommelier?

JB – I did. I started when I was 21 years old. I started in wine retail and from that decided I wanted to be a Sommelier. I went out to California and went through the training. I worked at a few restaurants and the last one I worked at was Anthony’s. That was a big step for me. At the time it was one of eighty Grand Award winning restaurants of the world according to Wine Spectator.

Angela Brown – It was quite an honor to be the lead Sommelier there, especially at such a young age.

JB – I felt that after college I was really searching for something. When I discovered wine it checked all the boxes for me. I just wanted to know as much as I could. I really immersed myself in it.

CP – How did the two of you meet?

AB – We were both in the wine industry.

CP – So after wine what did you do, since I know cigars didn’t happen for you yet?

JB – We got married and went on our honeymoon in Mexico. We were both burned out at our jobs and ready for something else.

AB – We never came back. We called up and quit our jobs. But we literally didn’t go back for a couple months. Eventually we had to go back and pack up all of our stuff into a container and ship it to Mexico.

CP – Where in Mexico?

AB – Playa del Carmen. It was right when it was getting going. The energy was great. We thought we could live there. So we did.

CP – So what did you do there?

AB – Well we knew we wanted to live there, but we had to figure out what we were going to do. The wine thing wasn’t big there. So we went through all the scenarios and at that point day spas were just becoming a big thing but there wasn’t one where we were. So we opened a day spa. We sold beauty products, did massages, hair, the whole thing.

CP – Did you guys have any experience in that field?

AB – Nope, none. I had one massage in my life.

JB – We just hired people.

AB – We were more of the concept people.

JB – We gave it a really modern and sleek design, which was really different for the people down there.

AB – We did that for a couple years then wanted to do something else.

JB – I was also painting a lot at that time. I had two galleries that were carrying my work and they were doing really well. I checked out of the spa thing pretty early on.

AB – Without much conversation he just kind of left one day and never came back.

CP – James, when did you start painting?

JB – I’ve been in and out of different art programs since I was about eight. I was always in some sort of program. I’ve always had art as a big part of my life. I went to art school in Dallas after high school, then switched to the University of Texas and finished the art program there. It’s always been something that I’ve done. In the states it’s a tough industry to break in to but I did have a couple galleries that carried my art after school but it never grew into anything until we went to Mexico.

CP – Did you art change at all after moving to Mexico?

CP – Did you art change at all after moving to Mexico?

JB – It did. Normally I was focused on printmaking and that similar style with a lot of paper work. In Mexico I started oil painting on large canvases because we had so much space there. I also had a lot more time to do it. There was a lot more color.

AB – So before long his art was outperforming the salon. I was working every day all day long, six days a week. But it worked out.

CP – When did cigars come into the picture for both of you?

AB – I casually enjoyed cigars in college. There were some nice cigar bars in Houston so I’d go in there with my girlfriends. I definitely wasn’t as passionate about it as I am now. It was an activity, something to do back then. I didn’t fall in love with it until we moved down here. Getting to know the whole process and what it means to have a really good cigar. That’s what really got me hooked. Now I take the time to enjoy cigars. It’s my time, it’s relaxing. Even if James isn’t interested I’ll go out and enjoy something by myself.

CP – But it’s a long journey yet before you guys moved to Nicaragua.

AB – We had many more adventures before we landed here.

CP – Did you get bored with Mexico?

JB – We were still in our 20s and had this adventurous spirit. We always looked for what’s the next thing. It didn’t take much for us to get stir crazy. We had a passion for travel and for a long time we had talked about going to Africa. I’m also a big Land Rover enthusiast. The only cars I’ve ever had have been old Range Rovers and Land Rovers. I loved the idea behind them, where they could take you and the travel behind that. We decided to buy a Land Rover and travel across Africa.

AB – So we sold everything and left with a suitcase.

JB – Our plan was to drive from London to Cape Town. We went back to the states for a little bit to prepare. We bought our Defender and kitted it out, getting it ready for our trip. Then we shipped it to England and started our trip. We went from London to Spain, then into Morocco and further into Africa. We spent about eight or nine months going through North and West Africa.

AB – We crossed the Sahara dessert. We didn’t have a satellite phone either or GPS. The idea was to get off the beaten path. We were experiencing the real Africa.

JB – So we did Morocco, Mauritania, Senegal, Mali, Burkina Faso, Ghana and the Ivory Coast.

AB – James skipped over the part when we got Mauritania when they were having a coup. We couldn’t get out. You have to have a Visa to get on to the next place. We were stuck there for a few weeks when we weren’t sure what was going to happen. We went with the flow.

CP – It sounds like that’s what you two do.

JB – Definitely. So by the time we got to Ghana we wanted to take a break. It’s an English speaking country so we could relax and recoup at the beach there. We went to the far west of Ghana and ended up finding this really remote beach about an hour away from the nearest town and about five hours from the capital, Accra. We just started camping on the beach. The locals didn’t mind. We were there for about a week and a half, packed up all of our stuff and headed out. We drove about two hours away to Cape Coast and we realized that we weren’t ready to go. So we turned around and went back. We stayed a couple weeks more and just fell in love with it. One of the guys from a nearby village said if we like it so much maybe we could buy the beach we were camping on. We realized that we only had so much money and we could keep going and spend it all or we could stay. So we decided to just try and buy the beach. We met up with the local chief and struck a deal for the land. We had this idea to build an eco-lodge there.

AB – The beach there was so beautiful. It was pristine with white sand. It turned out that it was a coconut farm. There must have been at least 300 coconut trees. We found out that we didn’t actually buy the trees. The trees were still owned by the farmers who planted them. They would come and collect their coconuts, and we were totally fine with it. We kept them nice and clean, trimmed and would get a few coconuts out of it. We have such a strong passion for doing things our way. We set out with a vision and by the end of it had built a really beautiful beach lodge. It was shocking to come down this horrible dirt road where the electricity and water stopped. Just keep going and eventually you’d run into our place.

JB – It took about nine months to build. We hired the locals and built in the traditional fashion with thatched roofs and then decked out the inside to be a bit more luxury. We had a great restaurant with one of the nicest bars in the country. We’d bring whisky and everything else that you never thought you could find in the middle of Africa.

AB – It was a place that people knew by word of mouth, and then word spread through all of the embassies. We had gotten into the guidebooks and developed a following. We had gourmet food with all local ingredients. The local fisherman would come to the beach with their dugout canoes. James would swim out past the break to their canoes and see what fish they had. Of course all of the guests were on the beach and they’d see him bring in the fish for lunch. Or lobsters would come in and that would be for dinner. The menu was never set; it was always changing depending on what we got that day. It was pretty fantastic. Sometimes now I feel disconnected to it because it was such a long time ago but that experience was one of the most incredible things I could have ever imagined for myself. It was really awesome.

JB – We were there for a little over five years. Parker, our son, was born there. He learned to walk in the sand. But the not-so-nice part of it was that each of us probably had malaria at least six times. Once a year at least we were deathly ill. But it was so common there. There were a lot of snakes and anything else you can imagine from the rainforest.

AB – The beach was literally backed up to the rainforest. So there was a period of time, three months out of the year, where everything would come out of the rainforest and onto the beach, because that’s apparently what they did. We didn’t know that beforehand, but we noticed a pattern. These weren’t your ordinary snakes; we’re talking black Mambas, Pit Vipers, Cobras and things like that. The fear started to set in. Especially since we had a child at that point. It’s fine for us to put ourselves in this danger, but to do it to a child felt irresponsible. Plus the family wanted to know Parker. We moved from there when he was three.

JB – We ended up selling the lodge to a Dutch guy and came back to the states. After being in Africa for five years we just wanted convenience and to live in a city. No snakes, no sand. We were done with the beach. We ended up moving to Denver in a high-rise condo. We tried that for about six months and hated it.

AB – We were playing house, and like everywhere else we only had our suitcases. We bought furniture and everything else to fill a three-bedroom condo. Then we were like, now what? We didn’t really want to be there anymore. Thankfully James and I have always been on the same path and feel the same things. I don’t think that when we left Denver, we knew exactly what we were going to do. We started this business that we were going to base out of Denver. But it was all about traveling through Central America. That way we could mix it half and half and rent out our condo while we were gone. After a few of those trips and we thought, why don’t we just stay there in Central America? We weren’t sure exactly where.

JB – We basically went city shopping and spent some time in Guatemala, Panama, Costa Rica, Nicaragua and eventually we decided to stay in Antigua, Guatemala. It was a picture perfect colonial city with cobblestone streets and perfect weather. The idea with the business was to give people the opportunity to experience what we experienced, the whole vehicle dependent travel and getting out into the middle of no-where. We took that idea and turned it into a travel company based in Central America. It was all geared around using Land Rovers to get to these very remote places in the jungle that you can’t normally get to. There are tons of Mayan ruins out there that haven’t had more than a few visitors in the past five years. The tracks are so tough you just can’t get there. You literally have to cut your way through. We focused on that and giving people that real off road experience.

JB – We basically went city shopping and spent some time in Guatemala, Panama, Costa Rica, Nicaragua and eventually we decided to stay in Antigua, Guatemala. It was a picture perfect colonial city with cobblestone streets and perfect weather. The idea with the business was to give people the opportunity to experience what we experienced, the whole vehicle dependent travel and getting out into the middle of no-where. We took that idea and turned it into a travel company based in Central America. It was all geared around using Land Rovers to get to these very remote places in the jungle that you can’t normally get to. There are tons of Mayan ruins out there that haven’t had more than a few visitors in the past five years. The tracks are so tough you just can’t get there. You literally have to cut your way through. We focused on that and giving people that real off road experience.

AB – That was a unique experience. We’d incorporate the beautiful safari-like tents. We wanted to make a safari in the jungle with nice food, whisky and cigars.

JB – We always end up doing things that we like. We see something and we say that we could do that or even do it better. We are both design inspired. We’ve stayed in so many places and beach lodges that we’ve had all these ideas.

AB – That’s what’s important to us, we always want to put our personal touch on things.

JB – We just want to incorporate the things we like and offer that to other people. We have lived a different lifestyle and want to be able to offer people the same thing. Just pull everything together and turn it into a business.

CP –How did cigars play into this?

JB – That’s pretty much what had started all of this now. With the travel company we mainly focused on Guatemala and Belize because that’s where the densest rainforests are. We’d also travel all the way through Central America; from Belize to Panama for example. We ended up spending a lot of time in Nicaragua. After we came here we wanted to incorporate cigar tours. I wanted people to be able to see that. We never really experienced anything like that until we did trips here. Seeing the process and tobacco fields and every step of what goes into making a cigar and meeting the people. As we ran the travel company cigars were always in the back of my mind. Ever since then I wanted to do something with it. It was like wine. I was in it and wanted to learn everything I could about it as fast as I could. We met Armando Leiva, who is our production manager now. He was working at a different factory then but met him through one of the tours we did. I was a sponge and learned everything I could from him. I asked him so many questions and wanted to do every step of the process. I spent a couple of years learning from him.

AB – It turns out that James and Leiva just work really well together. Together they can make some awesome stuff.

JB – We have very similar palates and have a lot of the same likes and dislikes when it comes to cigars. I decided that I wanted to blend my own cigar just for the hell of it. Basically that turned into making cigars for the clients that we had on our trips. They would get our company branded cigars to have on the trips. They fell in love with them and wanted to know how they could order more and get their hands on them. So then we thought that maybe there was something there. As a cigar consumer I was really bored with the industry for a long time. I felt like everything I was smoking felt repetitive of something else. Once I got to play with tobacco and really figure out what I do and don’t like, it really opened my eyes to the possibilities. Once I started making cigars for myself I realized that there probably were a lot of other people out there like me who wanted something stronger and bolder and what I consider more interesting. So we decided to do Black Label. With the branding we wanted it to be something that was different. Nothing really spoke to me as a consumer. It was 2012 when we really sat down and worked on blends and branding.

CP – Why did you choose the name Black Label Trading Company?

JB – Well everything that’s out there that has “Black Label,” like Partagas and Tatuaje, for a lot of people it’s their limited release cigars. We felt like all of our cigars were that. We wanted all of them to be like a special release.

AB – Even Ralph Lauren has Black Label. It’s like the next step up and that’s where we got our inspiration.

JB – We specifically did Black Label Trading Company because we didn’t want the brand 100% to be tied to cigars. We didn’t know what we might want to do with it in the future. We wanted to create branding that could go with anything, whether beer or spirits. We wanted to create a brand that is versatile and that can grow with us. I just wanted it to be semi edgy, a little dark, a little gothic. Anytime you’re dealing with skulls there is a really fine line between cool and cheesy. We wanted our stuff to be more elegant. I wanted it to appeal to a certain group of people and spark something in them like it does for me.

CP – I have a feeling you’ve been wearing all black for a lot longer than you’ve had your cigar company.

JB – I think I started wearing black when I was thirteen. I was that kid. It’s funny because I’ve been through so many phases of my life where I’ve had to wear suits and ties, tuxedos and all of that. But finally now I can dress like I did when I was thirteen. That’s the thing, it’s always been a lifestyle thing for me. It’s me, not just some image I’m trying to create. But I think that’s why it works because it is genuine. I don’t try to be the face of the brand, but it makes sense because it is an extension of who I am. I treat my art the same way. I want every cigar to have a specific feeling and evoke that feeling when you smoke it. It has to have a look that represents what it is, and that comes from inside.

AB – That’s one of the best advantages that we have. Everything can come from the heart. It’s all authentic. We aren’t going out and saying skulls are hot so let’s find someone to design it and make it trendy.

CP – Have you been painting through all of this James?

JB – For the most part. I painted a lot when we were in Guatemala. There were nice gallery options for me that did really well. I spent a lot of time developing a new technique there that I’ve used on all of my recent work. Now it’s transitioned into more graphic design and working with the branding. So I have that as a creative outlet. I can create totally new artwork for each of the brands that we do.

CP – Why did you choose to use skulls and some more of the morbid side of things?

JB – I don’t know, I’ve just always been into it. Halloween was always my favorite.

AB – If you see all of the names of our brands and art, they all kind of came from the time when we were in Guatemala. There were a lot of ceremonies around death. It’s more of a beautiful thing. We have to deal with it. It’s that beautiful elegance that is in all of us. The Latin culture and especially in Guatemala led us down this road.

JB – I just love it. I love the old colonial churches that are dark and the imagery is on the darker side. It’s always so intriguing to me. We spent about a year and a half figuring out what the branding would be. We pretty much started it as a pet project. We still had the travel company going so this was a fun thing to do. We started small and wanted to keep it that way. Then we also decided that I didn’t want to come across as just another guy with a cigar. One thing that ended up being beneficial to us is that we didn’t know anyone in the cigar industry. Not one person. I didn’t know a rep, retailer, cigar maker, anyone. The only person I knew was here in Nicaragua and that was Leiva. Ignorance was bliss. We were going to launch with six lines because we wanted this to come across as a brand. We want to sell the brand, not just a cigar. We wanted to paint the picture and have a presence on the shop shelves so you can feel the brand. Once we started meeting people they were telling us what a horrible idea it was and that it was the worst thing we could do. But we didn’t care and went for it. Fortunately it worked out and people understand the concept. We didn’t put too much focus on it because we were in Guatemala. We had a couple shops only. Somehow, someway people started talking about the product and social media was blowing up. People were sending cigars to friends. Retailers were contacting us. At that point we thought we should put some more time and effort into it and be open-minded.

AB – I just really loved our travel company that I didn’t give being in the cigar industry that much thought. I was having a blast. I loved it as a project and being ale to have them for our clients. I wasn’t ready to quit our travel business. So for the first six months I wasn’t that involved with the cigar side of things.

JB – I decided that I was going to the states and try to sell cigars even though I knew nothing about it. I was basically a vacuum cleaner salesmen going door to door. I figured that since we’re from Texas that I could start there and that would be our tie in. We ended up landing accounts and they were turning the product. Little by little it grew, but it grew more than we expected.

JB – I decided that I was going to the states and try to sell cigars even though I knew nothing about it. I was basically a vacuum cleaner salesmen going door to door. I figured that since we’re from Texas that I could start there and that would be our tie in. We ended up landing accounts and they were turning the product. Little by little it grew, but it grew more than we expected.

AB – Eventually there was a conflict of schedule between keeping the travel company going and the cigar business. Watching things I became a lot more interested in the business side of cigars. I started to see all the ways I could help. I had a background in marketing and communications. Little by little we realized that we had to sell off the travel company and focus on this. I still get a little sad about it. But we’ll still do it on our own.

JB – It was one of those things where we were very ignorant to what it took to run a cigar company. We didn’t anticipate all of the time it took in Nicaragua and being on the road. At first I was going back and forth to Guatemala and Estelí once a month trying to keep it all organized. Everything was going well and building up. The factory that we were working with basically screwed us. The tobacco we were buying to go into our product was not going into our product and instead was being sold out of the back door. The product that was supposed to be aging for ninety days was going into cellophane and boxes from the rolling table and shipped. At one point we received a shipment of probably $40,000 worth of cigars that were literally garbage. We threw them away. At that point we were about a year and a half in. We had a lot vested in it. I wasn’t interested in working with another factory. We couldn’t afford it and it didn’t make sense.

AB – Thankfully James had such a good relationship with the production manager from that factory that he took James aside and told him what was going on, the truth which you never hear. So he said if we ever wanted to do something on our own that he would be willing to help. So that’s when we decided to do the factory. It gives me chills because of the way that happened.

JB – We were either going to close up shop or go all in. This was late 2014. Obviously it was a huge undertaking to go into the factory side of things but it was really our only option.

AB – We weren’t going to accept mediocre product with our name and our branding. We couldn’t. It represents us because it is us. We aren’t going to sell crap. So then we decided that it was worth it for us to move here to Estelí full time and do it. We need to know that everything we are doing is good.

JB – We opened the factory. It was a whirlwind because we couldn’t afford to waste time. We had already lost a lot of product and a lot of time. Basically starting from scratch.

AB – And maybe even backwards a little bit because a few people had already gotten those shitty cigars.

JB – We didn’t know what to expect. Didn’t know if people were going to sell us tobacco or if people were going to come work for a couple gringos. Leiva was always like, don’t worry. He has a lot of great relationships. We were able to get the premium grade A tobacco that we wanted in the quantities that we needed. A lot of people that he knew were able to come work and roll for us. It was pretty quick getting everything up and going.

AB – It didn’t go without its challenges. We were the new factory in town and being gringos some people saw an opportunity. They’d come and try to sell us tobacco and thank goodness James looked at it and said hell no. I think the message got out pretty quick that we weren’t idiots. Little by little we weeded that stuff out. In the first six months we had to deal with it but now no one messes around with us.

JB – I think one thing that was always in my head since I started coming to Nicaragua and seeing the process was when I compared what you could do, with what people were doing and saw that there was a huge opportunity there. For me I knew the way processes should be done and I knew that a lot of people weren’t doing them in order to get the tobacco to the quality that it could be at. So having the factory was really a weight off of my shoulders because now we could control every single step of the process and getting done the way that I wanted it done.

AB – We could sleep better at night.

JB – That really started to show. We had a lot of relationship fixing, re-launching and rebuilding the brand.

CP – How many shops did you have at that time when you needed to rebuild?

JB – I’d say a little over 100 shops.

CP – How were you able to explain to them what happened and keep their business?

JB – Thankfully a lot of them understood and were really supportive. Some dropped off but it was really about getting the information out there and teaching them why it’s different now.

AB – I think it shows that anyone who knows us here can respect the commitment that we have. If they had a problem before, they try it now and realize it’s night and day. We really make beautiful

cigars and are living and breathing it. I thought we were spending a lot of time on it before and that we thought everything was fine, but the three weeks a month that we weren’t here before wasn’t enough and things were going wrong.

JB – Having the factory also allowed us to be as creative as we wanted to be.

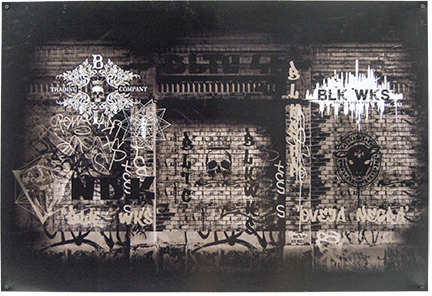

AB – That’s when we started Black Works.

JB – We were able to develop a lot of limited releases for Black Label also. Working with interesting tobaccos and interesting things that we didn’t have the opportunity to do before. It really opened the door for us. We could do what we wanted to do how we wanted to do it. We still have our six core line brands also. The market at the time was always: What’s new? What are you doing now? Everyone wanted something new. We decided we didn’t really want to go down that road. We didn’t want to make cigars that were one and done. There is no reason for it. There’s no secret tobacco that we’re using that we’ll never be able to use again. We figured that if we make a great cigar there is no reason that we shouldn’t be able to keep making it. So our limited releases are just annual releases that come back at the same time every year. People can feel like they are getting something new and for people who love the cigar can have this anticipation knowing it’s coming back. It really helped at the time to compete with a lot of the other companies that were pushing out a lot of new product. For a while it was a fight to compete in order for people to get the product. It seemed like for everyone, what was the everyday core line cigars were fizzling out. There was just so much new stuff coming. At that time as well, we wanted to do something new but not sure what. We had a lot of ideas. I had been rolling cigars and making blends that I had been smoking around the factory and really enjoying. With the sizes that I liked, they didn’t really fit the Black Label portfolio so to speak. The Black Label to me, while it is boutique, it is a little more mainstream as far as the sizes that we do. We had all these cigars that didn’t quite fit. That’s when we decided to launch Black Works Studio in late 2015. We wanted to showcase the factory and show people the type of cigars that we could make and how innovative that we could be. That sparked the Killer Bee, the Green Hornet and the NBK which are cigars that are very difficult to make and require a lot of attention to detail. They are what we consider more of the connoisseur or cigar geek type of cigars, which may not be the typical Black Label smoker. We very much treat the factory like a studio. We’re constantly playing with ideas and putting things together. We launched and didn’t know what to expect. It was very new. Not only was it a couple of new cigars, it was a whole new company. The cigars got out there and really snowballed. It grew bigger and faster than we had anticipated. We really had to slow it down. At one point we weren’t taking on new retailers. There was a big growing period in 2015 and 2016. As that continued we felt that the factory we were in was just getting smaller and smaller. As we ran out of space we knew that we had to do something. Either build on where we were or get a new location. We rode it out for the rest of 2016, then moved the new location here at the end of October. It’s been really good. Black Works was kind of the catalyst that took things to the next level for us.

CP – So is Black Label the umbrella for the company?

JB – I look at it like Oveja Negra (Black Sheep) is the umbrella, which is the factory. Then we have two brands, Black Label Trading Company and Black Works Studio. I think the style of cigars and imagery are both very different. It’s hard for us to differentiate it with people, but that’s fine it still works out.

AB – We were thinking it would be a different brand but it’s worked in our favor. Anyone who carried Black Label before is likely carrying Black Works. It felt like it was just one even though they are both very unique.

AB – Last Rights, Royalty, Salvation, Benediction and Lawless.

CP – So what sizes do you both like to personally smoke?

JB – I’m definitely a smaller ring gauge person. I really don’t like smoking anything over a 50 ring. That would be my max. My sweet spot is around a 42 or 46 in any length.

AB – My favorite is a 50. I used to smoke 60s that was my thing. When we first started Black Label that was all I smoked. It was my favorite. I started big but over time it has gone smaller and smaller.

JB – It’s kind of funny because when we launched Black Label in 2013 obviously big ring gauges were more popular then. So we did a chunkier robusto, did everything in a 60. Every year I want to cut the 60s. They still sell a lot so we really can’t.

CP – It seems that the more people enjoy cigars and get in the industry they go to the smaller rings, while a lot of the consumers out there go for the big ones.

CP – It seems that the more people enjoy cigars and get in the industry they go to the smaller rings, while a lot of the consumers out there go for the big ones.

JB – We didn’t know what to expect with Black Works and Killer Bee, a petit corona is our number one selling cigar. I would have never thought that.

AB – We actually have to limit the Killer Bees and Green Hornets because they are so popular. Everyone wants them and they are a time consuming cigar to make. We can’t flood the market, only little by little.

CP – How is the process with the FDA going since you began after their predicate date?

AB – We started the registration process and are just going along with it.

JB – We already had a nice size portfolio before August 8th, so we didn’t hammer the market with a bunch of new stuff. We had already mapped out the next couple of years for Black Works with a lot of cigars that we had planned to grow with. Those are what we focused on getting in, just so we can have new things and grow for the future. We’re doing what we have to do. I think it’s still really frustrating since we are all really in a state of limbo since we don’t know what to expect.

AB – Being so creative it was really depressing when we found out what was going on. We have so much more that we want to create. We had plans of other things and so that part was really upsetting.

JB – What bothers me is that we don’t put out another cigar just to sell more cigars. What I love about it is how our consumers respond to our cigars. When we put out the Boondock Saint for example, people went nuts for it. They love it. To not be able to see that in the future and not being able to be creative and hearing people’s feedback is really frustrating.

AB – You feel that your hands are tied. Thankfully we have a great portfolio, but there is just so much more that we can do.

CP – You have created and designed all of the art you use?

JB – Everything.

CP – What inspires your ideas?

JB – I’m all over the place. I love having influence from pop culture, whether music, movies or art. Things that I’m into translate into what I’m doing. When I decide to blend a cigar I have an idea of what I want it to be, and then once the cigar is finished and I smoke it, I realize the individual character that is in it. That’s what sparks the idea for whatever it is going to be. Whatever feeling it evokes as I’m smoking it the branding gets built around that.

AB – The consumer has created a lot of other elements that we never anticipated. Like WuTang Wednesday. Every Wednesday people smoke a Killer Bee. Then we have Black Friday, but that all comes from the consumer. It’s not something we drove. Some retailers have caught on to that and they’ll do Black Friday events. It’s just so cool. Then some people started Morphine Monday. It’s not something we planned at all.

CP – So you’ve gone from the colors of Mexico, back to black and white.

JB – Back to black and white. Full circle.

CP – Now online we have seen a lot of products, shirts, cutters and lighters as well.

AB – That’s another thing that has been consumer driven. We created it for James to have at events. The next thing you know people want that t-shirt, whatever the design is, or the cutters or lighters. I think that is one avenue where we can be really creative and the FDA can’t do anything about it. It’s a fun outlet in response to what people want.

CP – It seems so easy listening to you both but that is definitely not the case. It’s a very unique life experience so far and interesting how things led to this.

AB – I can’t complain. I feel very fortunate. We have had a nice ebb and flow and have been open to new experiences and then share it with people. We are very passionate and love to share that.

CP – You have a beautiful aging room here at the factory, can you tell us a little about that?

JB – Some people use a similar system. The reason being is that when you create a wheel of cigars you’re dealing with a smaller quantity in a paper bundle. You’re not getting a lot of interaction. Tobacco is like a sponge anything that touches it or is around it will manipulate the tobacco. The traditional way of doing what we do is in a closed box, opened on one end. Like everything else we wanted the aging room to be more of a showpiece and something really beautiful. We wanted to apply that same concept of putting a lot of cigars in a smaller closed space. Where the cigars interact with the cedar and themselves, but make it beautiful. We wanted it to have a great feel and almost look like a wine cellar.

CP – It’s clear that the entire factory is different and very unique. It’s very peaceful.

AB – We love coming to work. We’ll even come in on the weekends. It’s a happy space for us.

CP – How did you find the cedar to use? That is not an easy task these days.

AB – When we moved in to the new factory it was filled with all of this old wood that had been here for more than 20 years. This was a box factory in the 1990s. When we cleaned the place out we found all of this old cedar that had been sitting for so long. So we were able to repurpose it for what we needed.

JB – We were really lucky. You can no longer harvest Spanish cedar in Nicaragua. To be able to get it is very rare. Our carpenter was completely worried about transporting it from here to his shop because if the police stopped him with real cedar in his truck he’d be in serious trouble.

AB – It’s like finding gold. You want the real cedar and most of the stuff you see now just isn’t.

CP – It was meant for you to be here.

AB – It’s definitely a happy workplace and people enjoy it. It was actually a big deal for the workers moving from the center of town, where they could go out and have lunch with friends and come back to work. So coming out here we were worried that we were going to lose people. That was the most troubling thing, who isn’t going to want to do this with us. We heard some feedback about the transportation being expensive for the workers everyday. We paid everyone’s transportation until we could figure it all out. We didn’t want that to hold us back. After a month we added up the costs. The next month, we went out and bought a bus. We have a driver that has a route and picks everyone up. But we didn’t lose anyone. We have about 35 or 36 employees and ten teams of rollers.

JB – It was a learning curve for all of us just because we do things so differently. Most of these guys came from factories where they were just hammering out cigars just to hit the numbers they were given as a daily target. Quality may or may not be a focus. It’s all about production. It was an interesting process to get these people to slow down and wrap their heads around what our ideals are and why we do what we do. Now our guys really take pride in what they do. They have started to get it. At the end of the day they feel that we are making a product to the best of our abilities.

AB – The buncheros like to smoke cigars while they work and the rollers are starting to get into it. It was the first time I had ever seen that.

CP – There are a lot of factories, surprisingly where you don’t see one person enjoying a cigar.

AB – We get excited about it. They should be lighting up the cigars so they can know and understand what they are making.

JB – I don’t trust a bunchero that doesn’t smoke cigars.

CP – Like a chef that doesn’t eat.

CP – Like a chef that doesn’t eat.

JB – Exactly. You need to know what it’s like.

CP – We’ve noticed a lot more Lieberman machines out there these days (a machine that rolls the filler and binder together). Do you use them or do you hand roll everything?

JB – It is what it is. There are certain things we use them for. A standard robusto for example since you get a cleaner, more even bunch. There are some cigars that have to be hand bunched. Our Nocturnes and unique shapes really need to have a hand feel for where the tobacco placement is. There are good and bad sides to it. The problem is right now a lot of newer, younger buncheros don’t bunch by hand. They all use the machines. It’s one of those things.

AB – It’s scary to see because you have to wonder if that technique of hand bunching is going to die out.

CP – It’s interesting too to see that a lot of the newer generation doesn’t want to make cigars.

JB – We do have younger employees. But the ones that we’ve had are always looking for what their next job is going to be. They want to go to school and become a lawyer or whatever. It’s one of those things where it’s become one of those transient jobs for people. They’ll work in a factory until they finish school. Then they want to move to Granada or Managua or somewhere outside of Estelí. It is weird and scary for us to think about that. There is such a huge industry here in Estelí and it’s a struggle to find people who want to work in a cigar factory.

AB – There are signs everywhere in town that people are looking for buncheros and rollers. But that will lead to an increase in pay, which is great for them. They do have the upper hand. We just raised all of the prices and wages for everyone this year. We don’t want people to feel the need to go somewhere else. We want people to be happy to be here doing what they do. If it comes down to a pay increase we’ll take care of it.

JB – It also comes down to the quality of the product. You don’t want a transient group of rollers and buncheros because you aren’t maintaining a consistent product. Everyone bunches a little different and has their own unique style. If you’re making cigars with someone for years and then you have to do it with someone new, it’s going to be different. For us it’s important. We want our people to stay here.

AB – We have managed to keep all of our original employees except for one team. They ended up leaving and got offered an opportunity in Costa Rica where they were going to get paid double. They have since come back and wanted to work with us again.

CP – It’s nice to hear people support the pay increase, which isn’t always the case.

JB – Even today there is a reason that there isn’t a lot of tobacco tourism. A lot of factories don’t want people to see that side of things and pull back the magic curtain. A lot of people have this romantic idea of where their cigars are being made, with palm trees and shit everywhere and all colonial buildings. It’s just not all that way. So a lot of people don’t want to burst that bubble and show them that no, this is a factory. There are a lot of smoking mirrors in this industry.

AB – At the end of the day it is a factory. We have tried to work around that concept but it is a factory.

JB – It was funny because we pay our rollers and buncheros more than double what they would make in most other places. I don’t want them to make more than 300 cigars a day. Even if they can I don’t want them to.

AB – We look at how much each team is rolling and if it gets over a certain number I’ll go and talk to them. That’s not what we’re about. It’s great to help the bottom line but it creates the worry that they aren’t doing everything right.

JB – They make more money here rolling fewer cigars than they make somewhere else rolling two or three times as many cigars. They had a hard time with that.

AB – It took a while for them to understand that concept.

CP – James, can you tell us more about your art and style (James’ art was featured on the cover of Volume 11 Issue 4)?

JB – It’s all based on work that I did when we lived in Guatemala. I developed this interesting technique. Like I said before I worked a lot in printmaking, lithographs and silk screens and things like that. I wanted to come up with a new process where I could come up with a one off, or individual pieces of art but still have it feel like a print, which is difficult to do without using some sort of block or printing process. I work with really heavy duty, heavy weight watercolor paper. I start a base image out of pencil and then I take it step by step. Whatever I want to come through as white gets a coating of clear wax over it, then I ink over another color, like black for example. Everything I want to come through at the end in black gets another coating of wax and so on and so forth for every color. By the end of it you can’t tell what it is, just a big thick coat of wax covering the whole thing. Then I go through and remove all of the wax. Once I do that the image comes through.

AB – I have never seen or heard of this being done before. It’s something he developed.

JB – I have a good idea of what it’ll be at the end. But what I like about it is the uniqueness and randomness of it. Working with the wax you get a lot of drips and other non-controlled aspects of it. It comes out as it comes out. That’s what I like about it. It has freedom. Once the wax comes off you can see that in it, you can see the movement. There isn’t any particular or certain design mapped out.

CP – That has to be exciting for you too.

JB – It is.

AB – He called me one day and told me to come home quick. He showed me what he had done and was so excited with it. It was really cool to see. That was in his studio in Guatemala where he painted all the time. There were a lot of galleries and showings he did.

JB – I did a lot of oil painting in Mexico. I never really felt like that was my strongest medium. I wanted to come back to doing something with paper. I was experimenting with a lot of things. I always liked working with inks more than paint. I just like the quality and finish of it. It really grew out of that. I don’t particularly like the process of silk screening. I do like lithographs, but it wasn’t possible for me to do that then. So my new process really grew out of what I had to work with.

AB – You couldn’t get the materials to do everything he had been doing before. So he was left with no choice but to work with what was there.

CP – Do you have any other inspirations outside of your life experiences?

CP – Do you have any other inspirations outside of your life experiences?

JB – Obviously anything that you create is a personal part of yourself. Little bits and pieces of my life over time come out. I always focused on the darker side of things. Just because there is a lot of hidden beauty in there that a lot of people don’t see until you put it together in a certain way. The images have a lot of different things going on. You’ll see text and expressions of emotions and ideas. Everything pretty much looks like it doesn’t make sense. But then as you spend time with the piece it all comes together. What I wanted to do is if you look at it from across the room it looks like an abstract piece of art. Then you get closer and can see details and images in there.

AB – At one time in Mexico when he was painting, he did a townhouse in Mexico that looked really cool. James did all the artwork and it was just all stuff we wanted to hang in our house. Which we did. So when we decided to do our trip to Africa and put our condo for sale, someone came in and wanted everything in the condo. We thought they were talking about the furniture. But they wanted all of the art, everything.

CP – Has there been anything that was hard for you to leave?

JB – There always are.

AB – We’ve sold a few along the way that we’ve regretted. So we’ve stopped selling them.

JB – I did a show in Guatemala and they said it was just an intro for people to see the work. They said it wasn’t for sale. I picked my three favorites and inevitably they wanted to sell them.

CP – Did you sell?

JB – Yeah. At the end of the day don’t put it in the gallery if you don’t want to sell it. It’s a great compliment when someone wants to buy your work. I never want to say no.

CP – Do you have pictures or anything of all the work you’ve sold.

JB – No. We move on. One thing we regret out of everything that we’ve done is that we’ve never been really sentimental people. Our time in Mexico, or Africa, or wherever, we leave with a suitcase and go to the next place with a suitcase. So we don’t have anything.

AB – From Africa though we do have a really cool collection of masks. We went all over to remote villages. James studied a lot of African art so we did seek out some of that. When we did the big expedition road trip in Africa we were in a small Defender D90, which is small and only has two doors and the back end. The entire space we had available was planned out for things we needed. We had a fridge, a little shower, extra batteries and all of that. At one point we just started getting rid of a bunch of things. We got rid of clothes, pots and pans, the fridge, just so we could put in all this artwork that we found. Eventually we didn’t have much left.

JB – We were at a campsite in Mali. We were unloading a bunch of stuff. No one was around so we just left it. Someone will want it. It was cooking stuff and when we went back through that spot again the people actually brought it back and said they had been holding all of our stuff.

AB – We do want to have some of the things that represent our life experiences so we’re trying to be a little bit more conscious of getting rid of everything, but being at the factory and with the people really felt like home and became our family. It was it for us.

JB – It’s very different. We have two brands but I really just want to be a cigar maker. For me I feel like I’ve found my place. Which is a nice feeling to have. It’s been an interesting trip to land us here. I hope that comes across. One thing people like and can relate to is that it’s a new school cigar made with authentic techniques. Bringing those worlds together speaks to a lot of people. They like the uniqueness of our stuff. There isn’t a lot of tradition when it comes to the type of cigars we make or the branding. Obviously over the years we haven’t wanted to put down roots. We’ve been very nomadic. The great thing about what we’re doing now is that out of everything we’ve done this is it. This is what we’re meant to do.