Maduro Tobacco – It’s Not Just a Color

Maduro continues to be a loose term in the cigar world. Widely used to describe any cigar with a dark colored wrapper, the term has been commonly misconstrued. It doesn’t help that some cigars being produced today call themselves maduro based on color alone. In this article we dove into the good, the bad, and the ugly…truth, on what a maduro wrapper traditionally is and look at a couple assumptions that tend to go hand in hand with dark wrappers.

Maduro continues to be a loose term in the cigar world. Widely used to describe any cigar with a dark colored wrapper, the term has been commonly misconstrued. It doesn’t help that some cigars being produced today call themselves maduro based on color alone. In this article we dove into the good, the bad, and the ugly…truth, on what a maduro wrapper traditionally is and look at a couple assumptions that tend to go hand in hand with dark wrappers.

Maduro is a Spanish word that translates to mature, or ripe in English.

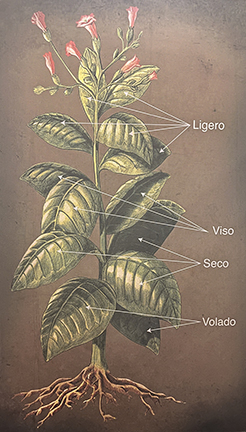

The translation of the word maduro is a great window that helps us look into an explanation for what this wrapper is all about. When putting the translation into cigar perspective one of the first things that comes to mind is how tobacco is harvested when it reaches maturity. A tobacco plant can be categorized into four basic groups of leaves called primings.

Volado:

Volado is the lowest set of leaves closest to the ground (first harvested)

Seco:

Seco is the middle set of leaves (second harvested)

Viso:

Viso is also a set of leaves found in the middle of the plant between Seco and Ligero.

Ligero:

Ligero is the top set of leaves. Ligero tobacco receives the most sunlight, has the most flavor and body strengths on the plant, and is the last priming to be harvested. Since the leaves on this priming are on the plant the longest, they have more time to mature on the plant, or “ripen on the vine,” if you will. The ligero leaves will also physically be thicker with a dense texture, which is a crucial component in producing authentic maduro wrappers. In order to correctly produce maduro wrappers one must use the thickest and heartiest leaves on the plant in order for them to survive the tedious fermentation process.

Side note about primings:

Tobacco plants are harvested in each of the primings listed above. The most common way to do that is to pick all of the leaves in each priming together, starting from the bottom Volado priming and working up to Ligero. Other manufacturers pick only two leaves from a single priming at a time. Depending on the size of the plant and how meticulous a manufacturer is will determine how they harvest the tobacco. In some cases there can be as many as 9 or more pickings.

Maduro isn’t a tobacco from one region or seed-variety (the broadleaf-seed maduro is perceived more often than not as one with the sweetest characteristic. Connecticut Broadleaf Maduro is probably the most recognized maduro in the market).

Maduro is a result of repeated fermentation that is seen through taste and texture in the smoke.

Maduro is a result of repeated fermentation that is seen through taste and texture in the smoke.

Here is the lo-down on fermenting and fermenting maduro wrappers: Maduro wrappers come from fermenting tobacco in pilones at higher temperatures and with more humidity than other tobacco types (Litto Gomez, for example, has said that for Maduro wrapper used on La Flor Dominicana, they may normally ferment tobacco at 125 degrees, while maduro is allowed to reach 150 degrees). Thick tobacco leaves (typically from the ligero priming) are used because they can stand up to the rigorous process of being fermented over and over again. During the fermentation leaves will slowly break down removing harsh characteristics from the smoke. Fermenting at a higher temperature is what gives the tobacco a darker than usual color. We need to reiterate that the only reason thick ligero leaves are used is because they can stand up to the extra fermentations and higher temperatures. Thinner leaves with less physical character would break down too much, and would not hold up to the process let alone produce the sought after taste and texture.

Fermenting tobacco is one stage in processing tobacco for cigars.

Fermenting is where the leaves end up after a 30-45 day stint in the curing barns and a process of sorting and selecting the leaves for filler, binder, and wrapper (the three basic components needed to make a premium cigar). Fermenting tobacco is vital when creating a cigar. This process makes the tobacco lose its acidity and nitrogen elements, which naturally turn the leaves darker and improve the actual combustion of the leaf. Without proper combustion, a cigar experience can quickly become an unpleasant problem.

So here’s how it’s done:

So here’s how it’s done:

After tobacco has been sorted, the leaves are put into “hands” of tobacco. A hand is just a set amount of leaves tied together at the stems. The hands are wet down, and then stacked one layer at a time into large, neatly formed stacks called “pilones.” Water (for humidity), and heat are two essential elements needed for fermenting tobacco. About half way up the pilone, some manufacturers will place a tube stretching all the way into the middle of the stack, so that a thermometer can be easily placed inside the stack without damaging any of the leaves. After a pilone is created, it is usually covered with a tarp or cheesecloth to retain the moisture and heat. In some instances, additional humidity is pumped into the room. The pilones will generate a lot of heat and temperature needs to be carefully watched. Manufacturers will record temperatures, and monitor the pilones daily. After the pilones temperature has hit a desired and controlled peak, then levels off for a few days they are broken down layer by layer in order to start the process over again.

Workers will shake out each hand of tobacco as it is removed from the old pilone, allowing the leaves to breathe and keep moisture evenly spread. They then evenly spray more water on each layer and restack the hands into a new pilone. After the new pilone is stacked and recovered, another stage of fermentation begins. The old pilone basically gets flipped from the inside out and top to bottom. The fermentation process can continue over and over again. If the pilones temperature is not monitored and excess heat accumulates, a few major problems can occur. It can make the pilone self-combust, it will turn the tobacco nearly black in color, and it will burn the essential oils in the leaf resulting in a charcoal or burnt-cardboard taste. It is hard to say that how much time tobacco requires in fermentation. Like everything else in the cigar making process and to quote our good friend Jose Blanco of A. Fuente & Co., “It depends.” A month usually seems to do the job for most cigar tobacco, but just like most other aspects from farming to post-harvest processing, the tobacco will let you know when it is ready depending on what the final goal that someone is trying to achieve. It is a combination of listening to the tobacco, and more importantly having the skilled hand, experience, and ear required to know what to listen for.

An end result in the natural process of fermenting a hearty tobacco leaf is that it will turn dark in color.

Maduro wrappers require a lot more time to ferment in order to develop a very rich and smooth, almost sweet characteristic. The thicker leaves require longer fermentation that results in a darker color. Every time tobacco is put into fermentation, it will become a little bit darker. Some companies cook their tobacco in fermentation at an extremely high heat, which turns the leaves darker quicker, but also results in a harsh flavorless tobacco with numerous negative side-affects. Some companies have used dyes to get their wrappers almost black. Some even dip a tobacco leaf in water and roll it around in their hands turning the tobacco black. For these reasons it is important not to assume that because a cigar is black or dark in color, that it is actually a maduro cigar.

Maduro doesn’t refer to color alone, which is a common misunderstanding today.

Maduro doesn’t refer to color alone, which is a common misunderstanding today.

Cigar making is a time-honored tradition not only by being passed through the generations, but because processing tobacco the right way can not be rushed if the goal is to produce the highest level of cigar tobacco possible. Not all manufacturers can wait for tobacco to tell them it is ready, thus have developed techniques to produce dark tobacco that they call maduro when it is simply stained wrapper tobacco that hasn’t turned dark through fermentation alone. A maduro wrapper that was given the proper fermentation process won’t turn your lips black or make your fingers look like they were dipped in ink. A lot of these darkening methods were created to meet the extremely high demand of the infamous boom in the mid-late 1990s. When demand jumped from 300 million cigars imported into the United States to 600 million, different problems arose. First of all there isn’t enough tobacco to make all of those cigars, and secondly, and only in some cases, companies would try to push the hands of time and create cigars from tobacco that was not processed enough or properly. That is especially true for maduro cigars.

Today, most people who think about maduro cigars correlate it with an extremely dark, almost black wrappers instead of the process that it takes to make a maduro wrapper, maduro.

A maduro wrapper should be rich in flavor with a very smooth texture in the smoke with a slight bit of sweetness on the palate. The sweet taste of maduro has a lot to do with the genetic make-up or seed-type of the leaf. The land where the tobacco was planted also plays a big role, more so than the fermentation, aging, or curing. Soil has organic micro elements that give tobacco the majority of its flavor. Tobacco is a direct representative of the land, soil, and air that it is planted in. That is why the same tobacco variety can taste completely different from one farm to the next in the same growing region and vary from crop to crop depending on which way the wind blows or how much rain fell that season. It all effects the tobacco. Broadleaf maduro is one of the most well-know maduro wrappers out there. It is said that the Broadleaf-seed variety has the sweetest taste, more than other types of popular tobaccos that are used for maduro wrappers. A lot of farmers and cigar makers plant this tobacco all over the world to get the unique qualities that each country and region provide, while being able to preserve the same Broadleaf sweetness that genetically part of that variety.

Maduro wrappers can be misleading just by appearance alone, especially to a newer cigar smoker.

They are generally dark, oily, rugged and look like they could bite your head off with sheer power alone. However not all maduro cigars are full-bodied/strength. Maduro wrappers don’t pack that strong of a punch because they have been broken down so much in fermentation. There are different factors that will give any wrapper its own unique attributes ranging from seed variety, to region grown, age, etc. An important bit of knowledge is knowing that a wrapper provides a cigar with the majority of its flavor, while the binder and filler are the driving force behind the body and strength. So the majority of body and strength comes from the blend of tobaccos, not the wrapper.